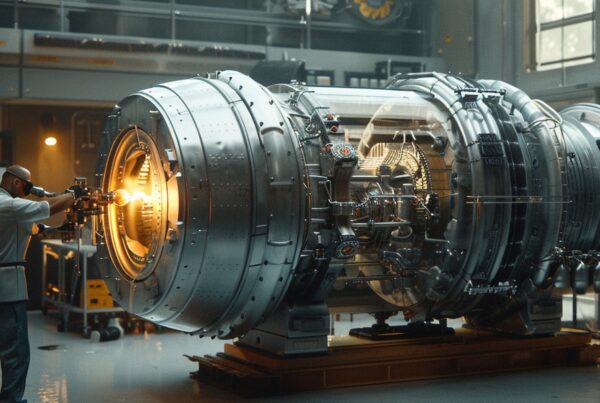

In the world of power generation and heavy industry, gas turbines play a critical role in delivering consistent, high-output performance. These complex machines are engineered to operate under intense conditions—extreme heat, high rotational speeds, and heavy mechanical loads. When downtime occurs or performance begins to dip, one of the first culprits often lies in the quality of gas turbine spare parts.

Using the right components doesn’t just improve efficiency—it protects long-term investment, reduces maintenance costs, and ensures operational reliability. In this blog, we explore how choosing high-quality spare parts can make or break turbine performance, and why working with trusted gas turbine spare parts manufacturers is key.

The Role of Spare Parts in Gas Turbine Efficiency

A single industrial gas turbine can contain thousands of individual components working in perfect synchronization. Among the most critical are:

- Turbine blades and vanes

- Combustor liners

- Nozzles

- Seals and gaskets

- Bearings and rotors

Each part is exposed to high temperatures and pressure. If even one of these components is manufactured with subpar materials or tolerances, it can result in:

- Increased heat losses

- Poor combustion efficiency

- Vibration and noise

- Accelerated wear and tear

- Unplanned outages

According to a report by Markets and Markets, the global gas turbine market is projected to reach USD 21.2 billion by 2026, with efficiency and reliability being the top concerns for end users. This only amplifies the importance of sourcing reliable and precisely engineered spare parts.

Real-World Impact: Case Study

A major power plant in South India faced recurring shutdowns due to microcracks in its second-stage turbine blades. After investigating, they found the parts were sourced from a generic vendor with no aerospace-grade material certification. The result? A total of 14 days of downtime, costing over INR 3.5 crore in lost output and emergency repairs.

Switching to certified components from a reputed gas turbine spare parts manufacturer eliminated the issue and extended the turbine’s maintenance interval by 18 months.

Why Quality Spare Parts Matter

1. Operational Efficiency

Precision-engineered parts reduce airflow disruptions and mechanical drag—boosting combustion efficiency and overall turbine output.

2. Longer Service Life

High-grade materials and coatings resist oxidation, creep, and fatigue—extending component life and lowering lifecycle costs.

3. Reduced Downtime

Reliable parts mean fewer unplanned maintenance stops, which in turn keeps the plant running closer to its optimal capacity factor.

4. Safety and Compliance

Turbine explosions or system failures can have catastrophic consequences. Quality parts adhere to international standards such as ASME and ISO, ensuring safety and regulatory compliance.

What to Look for in a Gas Turbine Spare Parts Manufacturer

When sourcing turbine components, consider manufacturers who:

- Provide full traceability of raw materials

- Follow ISO 9001 or AS9100 quality management systems

- Offer custom design and reverse engineering capabilities

- Conduct non-destructive testing and dimensional inspections

- Have proven experience with OEM compatibility

These factors help ensure that your turbine performs at peak efficiency and avoids costly setbacks.

Conclusion

In high-performance systems like gas turbines, quality is not optional—it’s essential. Every spare part you install has a direct impact on efficiency, safety, and profitability. Investing in premium gas turbine spare parts from a trusted partner isn’t just good practice—it’s smart business.

Looking for a reliable source for your turbine needs? BVPL Turbine Parts is a leading name among gas turbine spare parts manufacturers, offering precision-engineered components that meet global standards. With a strong reputation for quality, innovation, and timely delivery, BVPL is your go-to partner for ensuring peak turbine performance—every time.