With decades of experience and a legacy of excellence, we take pride in our role as a trusted partner for governments, defense organizations, and aerospace companies worldwide. Our state-of-the-art manufacturing facilities and a team of highly skilled professionals enable us to create precision-engineered products and make us a leading aerospace components manufacturer.

Beyond our technical expertise, we pride ourselves on fostering collaborative partnerships with our clients. We work closely with you to understand your specific needs, offering tailored solutions that address your unique challenges and contribute to your success.

We manufacture a wide range of aerospace components including a large variety of blades and vanes that power aero engines. As an aerospace components manufacturer we also manufacture structural and tolling components. We also have strong reverse engineering capability and can manufacture high precision, tight tolerance parts through reverse engineering for the civil and defense aircrafts.

Aero Engine Blade

High Pressure Compressor Blades

Material: Titanium – TA8DV

High Pressure Turbine and Intermediate Pressure Turbine Blades

Material: Nimonic 115

Aero Engine Blades and Vanes

Blades

Material: Inconel and Titanium

High Pressure and Low Pressure Aeroengine Vanes

Material: Aluminium Alloy

Reverse Engineered Aero Engine Blades and Blisks

Reverse Engineered Blades by BVPL

Material : Aluminium, Stainless Steel and Titanium

Blisks for Aero Engines

Material : Stainless Steel

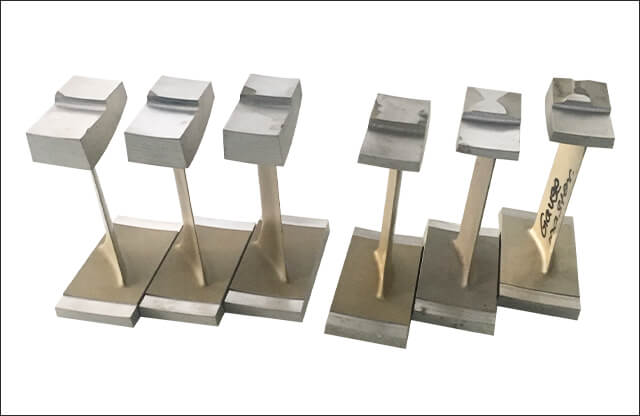

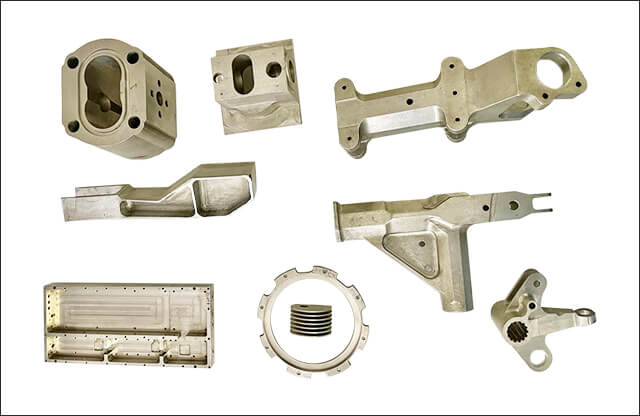

Aerostructures and Parts for other applications

Material : Aluminium

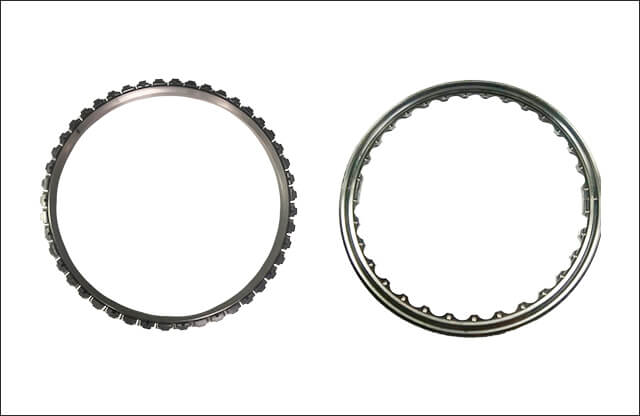

Aero Engine Inner Rings Assembly

Inner rings assembly Stage 1, Stage 2 and IGV (Material: Inconel 718)

Why Choose Aerospace and defense components manufactured by BVPL Turbine Parts?

- Our Expertise: With decades of experience in the industry, our team of highly skilled engineers and technicians is dedicated to delivering cutting-edge solutions. We specialize in the design, development, and production of a wide range of components, catering to the unique and demanding requirements of the aerospace and defense sectors.

- Quality Assurance: Quality is at the heart of everything we do. We adhere to the strictest industry standards and certifications, ensuring that each component leaving our facility is of the highest quality. Our state-of-the-art quality control processes guarantee precision and reliability, crucial in critical applications.

- Innovation: Innovation is the driving force behind our success. We continuously invest in research and development to stay at the forefront of technological advancements. Our commitment to innovation enables us to deliver components that are not only efficient but also environmentally sustainable.

- Product Range: Our product range encompasses a wide spectrum of aerospace and defense components, including but not limited to:

- Turbine Blades: We manufacture turbine blades known for their exceptional durability and efficiency, contributing to enhanced engine performance.

- Compressor Parts: Our compressor components are engineered to withstand extreme conditions, ensuring the reliability of critical systems.

- Structural components: We manufacture structural components for aircraft

We have decades of experience in manufacturing aerospace components from a range of raw materials including aluminum and stainless steel and difficult-to-machine super alloys such as titanium, inconel and nimonic.

-

Custom Solutions: We understand that each project has its unique challenges. At BVPL Turbine Parts, we collaborate closely with our clients to develop custom solutions that meet their specific requirements. Our engineering team is ready to turn your concepts into reality.

-

Global Reach: Our products are trusted by aerospace and defense organizations worldwide. With a global reach, we ensure timely delivery and support wherever you are.

-

Environmental Responsibility: We are committed to sustainability. Our manufacturing processes are designed to minimize waste and energy consumption while maximizing the use of eco-friendly materials.

FAQs

What does an aerospace and defense components manufacturer do?

An aerospace and defense components manufacturer designs and produces components for aircraft, spacecraft, and defense systems. This includes precision-engineered parts, electronics, and other critical components.

What materials are commonly used in aerospace and defense component manufacturing?

Aerospace and defense components are often made from high-strength alloys, composites, and lightweight materials like titanium to meet stringent performance and weight requirements.

How does quality control play a role in aerospace and defense manufacturing?

Quality control is crucial in aerospace and defense manufacturing to ensure the reliability and safety of components. Rigorous testing and inspections are conducted throughout the manufacturing process to meet strict industry standards.

How do I choose the right aerospace and defense components manufacturer for my needs?

Consider factors such as experience, certifications, adherence to industry standards, and a track record of delivering high-quality components on time. Ensure the manufacturer aligns with your specific requirements and standards.

We will be happy to provide/source any of these services along with our customer promise of competitive price, excellent quality and delightful customer service

Contact Us