At BVPL, we are dedicated to setting new standards in precision manufacturing. With a global reach and a commitment to excellence, we manufacture and supply high-quality engineering components to industries worldwide. Our unwavering dedication to precision, innovation, and customer satisfaction has earned us a reputation as a trusted partner in the field of precision engineering.

We are AS9100 (stringent aerospace industry certification) and ISO 9001: 205 certified. As a precision components manufacturer – we work with difficult geometries including intricate and complex 3D profiles and hard-to-machine raw materials with high nickel – chromium – cobalt content. We can also reverse engineer components for which there is no drawing or raw material specification.

Hydrogen Electrolyzer Components

ABS (Acrylonitrile Butadiene Styrene) components manufacture

for green hydrogen electrolyzer.

Aero Engine Blade

High Pressure Compressor Blades

Material: Titanium – TA8DV

High Pressure Turbine and Intermediate Pressure Turbine Blades

Material: Nimonic 115

Aero Engine Blades and Vanes

Blades

Material: Inconel and Titanium

High Pressure and Low Pressure Aeroengine Vanes

Material: Aluminium Alloy

Reverse Engineered Aero Engine Blades and Blisks

Reverse Engineered Blades by BVPL

Material : Aluminium, Stainless Steel and Titanium

Blisks for Aero Engines

Material : Stainless Steel

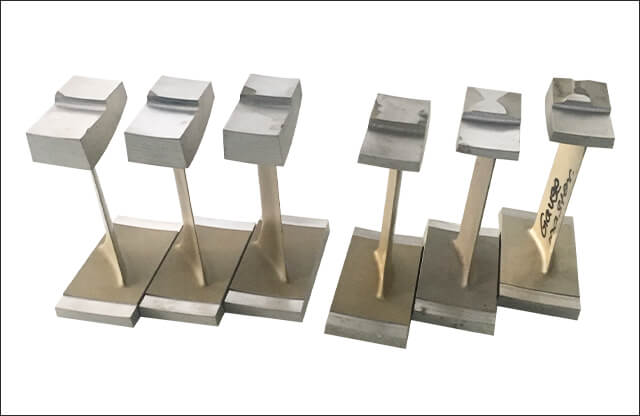

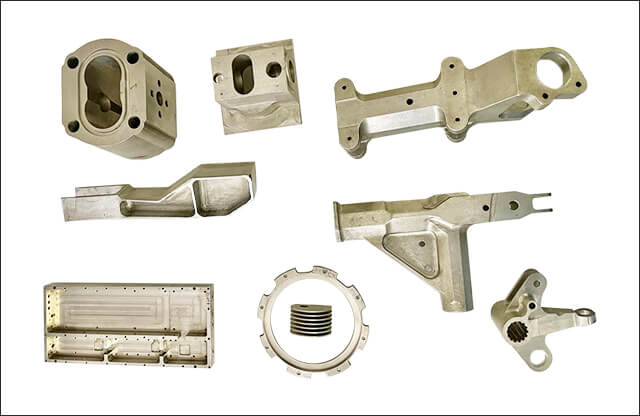

Aerostructures and Parts for other applications

Material : Aluminium

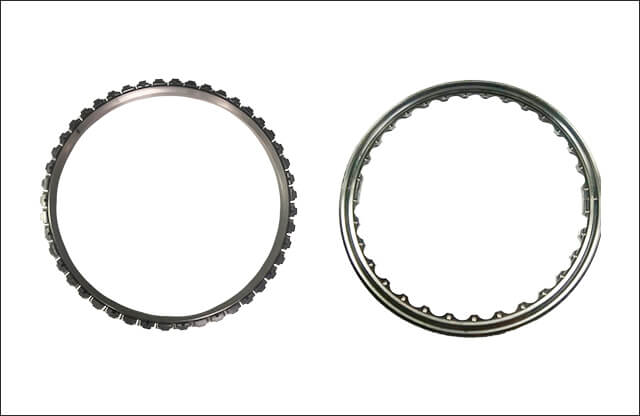

Aero Engine Inner Rings Assembly

Inner rings assembly Stage 1, Stage 2 and IGV (Material: Inconel 718)

Steam Turbine Blades

Example of steam turbine blade – Siemens

(Dresser Rand) Steam Turbine Blades Material: FV448.

Industrial Gas Turbine Shrouds

Examples of GE Gas Turbine Shrouds for Frames 5, 6, 7 and 9. We regularly manufacture these for the European, USA and Middle Eastern markets. Material: SS310, SS410, SS304, SS316, HR120 etc. We can provide these along with Hardface coating or Honeycomb.

Why choose Precision Components Manufacturer by BVPL Turbine Parts?

-

Our Expertise:

With decades of experience, our team of engineers and technicians possesses unparalleled expertise in precision engineering. We specialize in manufacturing components that meet the most exacting standards, delivering solutions that empower industries to achieve their goals.

-

Global Reach, Local Presence:

Our commitment to serving clients around the world is at the core of our business. Products manufactured by BVPL is exported and used worldwide

-

Precision Manufacturing:

We utilize cutting-edge technology, state-of-the-art machinery, and stringent quality control processes to ensure that every component we produce meets the highest standards.

-

Industries We Serve:

Our precision engineering components find application in a wide range of industries, including:

- Aerospace and Defense

- Oil and Gas

- Renewable Energy

- Automotive

- Medical Devices

- Electronics

- Custom Solutions

At BVPL, we understand that one size does not fit all. That’s why we offer customizable solutions tailored to your specific needs. Our team works closely with you to design and manufacture components that align perfectly with your project requirements.

-

Quality Assurance:

Quality is paramount at BVPL. We adhere to stringent quality control measures at every step of the manufacturing process and hold an AS9100 certification. Our commitment to quality ensures that our components not only meet but often exceed industry standards, giving you peace of mind.

-

Environmental Responsibility:

We are committed to sustainability and minimizing our environmental footprint. Our manufacturing processes are designed to be energy-efficient, and we strive to reduce waste and emissions. We are proud to contribute to a greener future while delivering top-notch precision engineering components.

FAQs

What types of industries do precision components manufacturers serve?

Precision components manufacturers serve a wide range of industries, including automotive, aerospace, electronics, medical devices, and any field requiring high-precision parts.

What are the key advantages of using precision components?

Key advantages of precision components include enhanced performance, tighter tolerances, improved reliability, and the ability to meet specific design requirements for various applications.

How do precision components differ from standard components?

Precision components are manufactured to extremely tight tolerances, ensuring high accuracy and consistency. This level of precision often results in superior performance compared to standard components.

What is high precision manufacturing?

High precision manufacturing involves the use of advanced techniques, such as CNC machining and precision grinding, to produce components with extremely tight tolerances and exact specifications. This ensures consistency and accuracy in the final product.

We will be happy to provide/source any of these services along with our customer promise of competitive price, excellent quality and delightful customer service

Contact Us