In the global push toward cleaner and more sustainable energy, industries and power producers are continually exploring technologies that reduce greenhouse gas emissions. Among these technologies, Steam Turbine Generators — a tried-and-tested powerhouse of industrial energy—are getting a second look for their potential role in decarbonization.

While often associated with traditional thermal power plants, steam turbines are now being integrated with renewable and low-carbon energy systems, offering a path to significant emissions reduction without compromising energy reliability. But can Steam Turbine Generators truly help reduce carbon emissions? Let’s take a closer look.

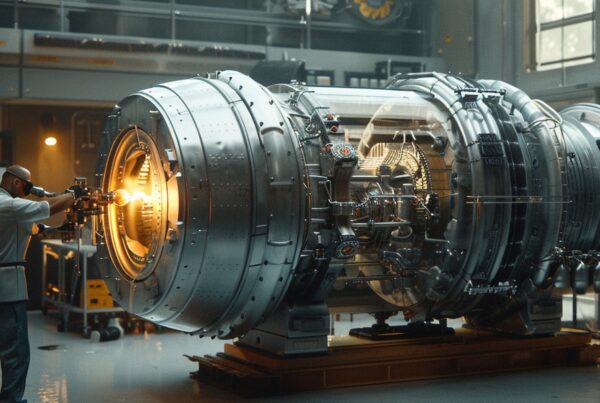

Understanding Steam Turbine Generators

A steam turbine generator converts thermal energy—typically from steam—into mechanical energy, which drives an electrical generator to produce power. This technology has been a cornerstone of global electricity generation for over a century. Its applications range from coal-fired power plants to nuclear reactors and combined heat and power (CHP) systems.

Today, innovations in steam turbine generators and cleaner heat sources are driving more eco-friendly power generation.

How Steam Turbine Generators Contribute to Carbon Reduction

Steam turbine generators play a pivotal role in the transition to cleaner energy systems by improving efficiency and enabling the use of low-carbon or renewable heat sources. Unlike conventional generators that rely heavily on fossil fuels, modern steam turbines can be integrated into sustainable setups such as biomass plants, geothermal stations, and waste heat recovery systems. Their ability to convert thermal energy into electrical power with minimal emissions makes them a valuable asset in efforts to reduce global carbon footprints.

1. Integration with Renewable Heat Sources

Modern steam turbines can be paired with biomass boilers, geothermal reservoirs, and even solar thermal systems to produce clean electricity. Unlike fossil fuels, these sources emit either zero or significantly lower carbon dioxide per kWh produced.

Example: In Denmark, several district heating plants use biomass-fueled steam turbines to supply low-carbon electricity and heating, reducing national emissions by hundreds of thousands of tonnes annually.

2. Waste Heat Recovery

Industries such as steel, cement, and chemical manufacturing produce massive amounts of waste heat. By installing waste heat recovery steam turbines, these industries can convert otherwise wasted energy into electricity—reducing fuel consumption and carbon emissions.

3. Efficiency in Combined Heat and Power (CHP) Systems

CHP systems that utilize steam turbines can reach efficiencies of 60–80%, far higher than the 30–40% efficiency of conventional thermal power plants. This high efficiency means less fuel is burned per unit of energy, leading to lower carbon output.

4. Retrofitting Coal Plants for Cleaner Operation

Some countries are retrofitting coal-fired steam turbine plants to run on natural gas, ammonia, or even green hydrogen—fuels that produce far fewer emissions than coal.

The Growing Role of Manufacturers in Clean Energy Transition

Innovative steam turbine generators manufacturers are driving the shift toward carbon-friendly designs. Features such as:

- Advanced blade materials for higher thermal efficiency

- Modular turbine configurations for flexibility

- Integration with carbon capture and storage (CCS) systems

are helping old technologies become part of the new energy future. India, in particular, has seen a rise in steam turbine generators manufacturers in India catering to domestic and international markets with energy-efficient and environmentally-conscious turbine designs.

Challenges to Consider

While steam turbines have enormous potential, they are not a standalone solution for carbon neutrality. Challenges include:

- The need for clean steam sources.

- High upfront capital costs for new installations.

- Technical expertise required for operation and maintenance.

Steam turbines, when part of a broader decarbonization strategy, provide a cost-effective way to cut emissions in high-temp, high-pressure industries.

Conclusion

Steam Turbine Generators are more than just legacy machinery—they are evolving assets in the fight against climate change. Whether through biomass, geothermal, or waste heat recovery, these turbines can significantly cut carbon emissions when used intelligently. For companies looking to invest in high-efficiency turbine systems, choosing the right partner is critical. BVPL Turbine Parts, a trusted name among steam turbine parts manufacturers in India, delivers world-class components and support. With precision engineering and a commitment to sustainable performance, BVPL is empowering industries to operate cleaner and smarter.