In an era where uninterrupted energy supply powers everything from smart cities to industrial production lines, the backbone of this reliability often goes unnoticed — steam turbine generators. These engineering marvels play a pivotal role in generating large-scale electricity with unmatched consistency and efficiency. As energy demands grow and power grids evolve, steam turbine generators have proven indispensable in delivering the kind of stable, long-term energy solutions that modern life depends on.

Used across turbine generator power plants—from thermal and nuclear facilities to renewable hybrids—these systems are not only reliable but also adaptable to different fuel sources. Their ability to run continuously with minimal performance loss over time makes them a cornerstone technology in global energy infrastructure. This blog explores why steam turbine generators are critical to maintaining a dependable energy supply, and how quality components and expert services from leading steam turbine generators manufacturers ensure their long-term success.

Understanding Steam Turbine Generators

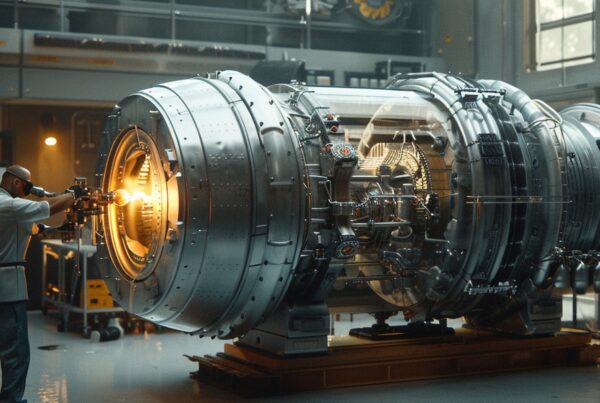

A steam turbine generator is a combination of a steam turbine and an electrical generator that converts thermal energy from pressurized steam into mechanical energy, and subsequently into electricity. This system is widely used in various types of turbine generator power plants, including fossil-fuel-based, nuclear, biomass, and even solar thermal facilities.

The basic mechanism involves:

- Steam produced from boiling water using heat sources.

- High-pressure steam directed onto turbine blades.

- Turbine rotation drives the generator to produce electricity.

The simplicity of the principle is matched by the complexity of the engineering, which is where quality and expertise from steam turbine generators manufacturers become critical.

Why Steam Turbine Generators Ensure Reliability

When it comes to consistent and large-scale electricity production, steam turbine generators are trusted worldwide for their unparalleled reliability. Their ability to run continuously, with minimal breakdowns and high thermal efficiency, makes them a preferred choice for base-load power in both industrial and utility-scale energy operations. Unlike many other systems, steam turbines can handle high loads for extended periods without compromising performance—making them the heartbeat of dependable power generation.

Example:

Take the example of the Vindhyachal Thermal Power Station in Madhya Pradesh, India—the largest power station in the country. Operating with a capacity of over 4,760 MW, this plant relies heavily on steam turbine generators to meet the growing energy needs of millions. The turbines used here have been running efficiently for decades, with carefully planned maintenance and parts replacements from reliable steam turbine generators manufacturers. This long-term performance showcases how steam turbines can deliver reliable energy 24/7, even under intense demand.

Let’s explore the numerous benefits that steam turbines offer:

1. Stable Power Output

Unlike some renewable sources that fluctuate based on weather conditions, steam turbines provide a consistent and predictable output. This makes them ideal for base-load power plants that supply energy around the clock.

2. Fuel Flexibility

Steam turbines can operate on a range of heat sources—coal, gas, nuclear, biomass, and even waste heat. This flexibility ensures they remain relevant across changing energy landscapes, especially in hybrid power systems.

3. High Efficiency with Combined Cycles

In combined-cycle power plants, steam turbines work alongside gas turbines, utilizing the waste heat from the latter to generate additional power. This increases the overall plant efficiency up to 60% or more, making it a highly sustainable solution.

4. Long Operational Life

With proper maintenance and support from specialized turbine generator services, steam turbine generators can run efficiently for decades. This durability adds significant long-term value and reduces the frequency of expensive replacements.

5. Grid Stability and Backup Power

In large-scale grids, steam turbines provide inertia and frequency control—two vital features for maintaining grid stability. In emergencies, they can serve as reliable backup sources, especially in areas prone to power outages.

The Role of Quality Manufacturing

To achieve the levels of performance and reliability required, it’s crucial to source parts from trusted steam turbine parts manufacturers. Precision in blade design, material strength, rotor balancing, and thermal resistance are just a few of the factors that influence operational success.

Manufacturers and suppliers must adhere to international standards and perform rigorous testing to ensure their turbine systems can withstand the physical demands of high-pressure steam and long operating hours.

Applications Across Industries

Steam turbine generators are indispensable in sectors like:

- Thermal power plants (coal, nuclear, gas)

- Industrial co-generation facilities

- Petrochemical refineries

- District heating systems

- Waste-to-energy plants

Each application demands customized turbine configurations and reliable ongoing maintenance from experienced turbine generator services providers.

Conclusion: Building a Resilient Energy Future

As nations modernize infrastructure and shift to sustainable energy, steam turbine generators will remain key to reliable power. Their proven efficiency, adaptability, and dependability make them an irreplaceable asset for both legacy and future-ready power plants. For industries looking to invest in high-quality, performance-driven turbine solutions, BVPL Turbine Parts stands as a trusted partner. As one of the leading steam turbine generator parts manufacturers in India, BVPL offers precision-engineered components, expert turbine generator services, and end-to-end support to ensure uninterrupted and efficient power generation.