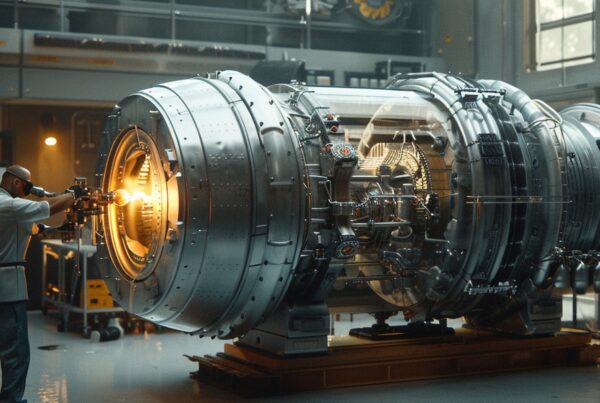

For generations, humanity has sought cleaner, more sustainable ways to power our lives. Today, hydrogen emerges as a frontrunner in this quest, offering a versatile and planet-friendly fuel source. But how do we unlock its potential? Enter hydrogen electrolyzer components, the unsung heroes of the clean energy revolution. At BVPL Turbine Parts, we believe in hydrogen electrolyzer components’ transformative power. We’re dedicated to developing cutting-edge electrolyzer technology that makes hydrogen production efficient, accessible, and sustainable.

Core Precision Components Of A Hydrogen Electrolyzer

1. Electrodes

The electrodes are the heart of the electrolyzer, where the actual splitting of water molecules occurs. There are two types of electrodes in an electrolyzer:

- Anode: The positive electrode where oxygen is produced.

- Cathode: The negative electrode where hydrogen is generated. These electrodes are typically made from materials such as platinum, palladium, or nickel that are excellent conductors of electricity and resistant to corrosion.

2. Electrolyte

The electrolyte is a medium that allows ions to move between the electrodes, facilitating the chemical reaction. Depending on the type of electrolyzer, the electrolyte can be:

- Alkaline Electrolyzers: Use a liquid alkaline solution (usually potassium hydroxide, KOH).

- Proton Exchange Membrane (PEM) Electrolyzers: Use a solid polymer electrolyte.

- Solid Oxide Electrolyzers: Use a ceramic electrolyte that conducts oxygen ions.Each type of electrolyte has its advantages and challenges, influencing the efficiency and application of the electrolyzer.

3. Membrane

A proton exchange membrane is crucial in PEM electrolyzers. This thin layer of material allows protons (hydrogen ions) to pass through while blocking gases like oxygen and hydrogen. This selective permeability ensures the separation of hydrogen and oxygen gases, enhancing the purity of the hydrogen produced.

4. Catalyst

Catalysts are substances that speed up the electrolysis reaction without being consumed in the process. They are usually applied to the surface of the electrodes. In PEM electrolyzers, precious metals like platinum and iridium are often used as catalysts. In alkaline electrolyzers, cheaper materials like nickel can be used, though they may be less efficient.

5. Power Supply

A reliable power source is essential to drive the electrolysis reaction. This power supply needs to provide a steady direct current (DC) to the electrodes. The efficiency of hydrogen production is highly dependent on the stability and quality of the power supply.

6. Cell Stack

An electrolyzer typically consists of multiple cells stacked together to form a cell stack. Each cell contains an anode, cathode, and electrolyte. By stacking multiple cells, the electrolyzer can produce more hydrogen, making the process more scalable and efficient for industrial applications.

7. Gas Separator

After the electrolysis process, separate and collect the produced hydrogen and oxygen gases. Gas separators keep these gases from mixing, maintaining the purity of the hydrogen.

Why are Electrolyzers Important?

Electrolyzers are the cornerstone of a hydrogen-powered future. They enable clean hydrogen production from renewable energy sources like solar, wind, or geothermal power.

This green hydrogen, produced without any harmful emissions, holds immense potential to revolutionize numerous sectors:

1. Transportation Unleashed: Emissions-free Mobility Takes Off

Say goodbye to tailpipe exhaust! Hydrogen-powered vehicles, from cars and buses to trucks and aeroplanes, are becoming a reality. Electrolyzers pave the way for clean transportation by generating hydrogen fuel that powers these vehicles with zero emissions. Imagine zipping through your city in a hydrogen-powered car, leaving only clean air in your wake.

2. Energy on Demand: Powering Homes and Industries Sustainably

Electrolyzers can also store renewable energy in hydrogen, acting as a giant green battery. This stored hydrogen can generate clean electricity during peak demand periods or when renewable sources are unavailable. This means a more reliable and sustainable energy grid that powers our homes, businesses, and industries with minimal environmental impact.

3. Industrial Decarbonization

Many industries, like steel production and chemical refineries, rely heavily on fossil fuels, contributing significantly to greenhouse gas emissions. But electrolyzers offer a game-changer. These industries can decarbonize their processes by using green hydrogen generated from renewable sources, significantly reducing their environmental footprint.

4. Beyond the Obvious: Hydrogen’s Diverse Applications

The potential of hydrogen goes far beyond these core examples. It can heat buildings, fuel ships, and power portable generators. As electrolyzer technology improves and becomes more cost-effective, we expect a surge in innovative applications across various sectors.

At BVPL Turbine Parts, we understand the pivotal role of precision mechanical components such as electrolyzers in unleashing hydrogen’s vast potential as a clean and adaptable energy solution.

Our expertise extends across various industries, and we’re excited to announce that more projects are on the horizon, spanning sectors such as transportation, energy storage, and industrial decarbonization.

Powering your business with Hydrogen

The potential of hydrogen is undeniable. With advancements in electrolyzer technology, we’re on the cusp of unlocking a clean energy future powered by hydrogen. At BVPL Turbine Parts, we’re proud to be at the forefront of this revolution as precision components manufacturers, and we invite you to join us on this exciting journey.

Contact us to learn more about our innovative electrolyzer solutions and how we can help you build a hydrogen energy strategy for your business.