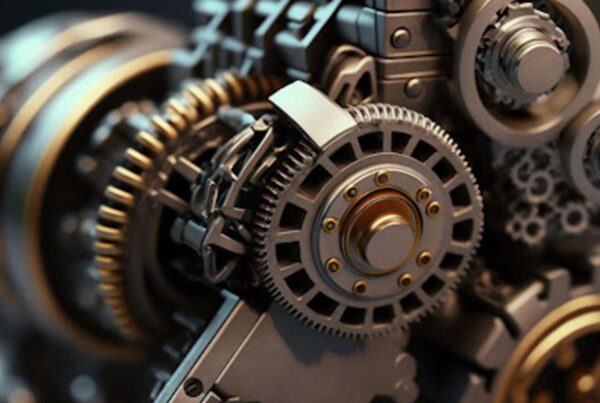

Precision mechanical components have brought a major transformation in many industries which includes aerospace, automobile, HVAC, and other sectors. They are known for high-level accuracy and superior quality. In this blog, we shall unleash the significance of precision mechanical components and why you must opt for them.

Significance of precision mechanical components for Industrial Projects

Let us look into the advantages of precision mechanical components –

1. High level of accuracy

Accuracy is the key to perfection. Being precise with specifications is a need for every industry. This creates a positive impact on the manufacturing systems. Every industry requires precise specifications for accurate cuttings. Precision machine components help in achieving accuracy with detailing for most industries.

2. Easy Assembly and saves time

The automation systems in precision machining help in the smooth process of assembly without any pauses or interruptions. It is fast, quick, and super -efficient which helps to save time. There is no manual system involved which reduces production time and boosts overall productivity.

3. Cost-efficient

Precision manufacturing helps reduce cost with zero-to-low errors generating positive outputs. Reduced errors help in boosting positive outcomes and reduce manufacturing costs. Proper financial planning can help reduce labor costs with better-automated efficiency.

4. Less raw material wastage

Precision machining helps to minimize raw material wastage and generates better quality by utilizing more material in the manufacturing process. Raw materials such as graphite, copper, and steel are considered to be expensive. Precision components help to save costs and boost higher accuracy.

5. Effective, fast, and safe production

Using precision components helps in effective, fast, and safe production due to automated features. This reduces accidents and injuries at the site which can be distressing and troublesome. With computer-controlled precision machined parts, the outcome is speedy and accurate.

6. Zero errors with no blunders

With the usage of precision components, the results are positive with zero errors and no blunders. The automated precision components begin after specifications are inserted which gives high efficiency. There are no blunders with automated system components.

7. Excellent functional prototype manufacturing

The precision component helps generate prototypes with the right end material ready for use. It has higher-quality testing for better functionality. Any kind of issue can be fixed with the expertise of engineers and designers before the final product is showcased to the end user.

Precision mechanical components are the main reason behind the major industrial revolution. Thanks to automated systems and techniques involved in precision machining, computers automatically remove the material to generate precise parts based on instruction through software. This allows fast, efficient, and safe production with no wastage and better usage of raw materials.

BVPL Turbine Parts has expertise in developing precision components for all its mechanical engineering parts which adds value to the overall functionality of the machining system. It is an ISO-certified company with manufacturing of high precision components at its best under qualified, professional, and skilled technicians.