A gas turbine is an internal combustion engine that converts the energy from fuel into mechanical energy in the form of rotational motion. It operates on the principle of using the energy released from burning fuel to produce a high-velocity stream of hot gases. These gases are then directed through a series of turbines and other components of gas turbine to drive a shaft, which can be new to power various machinery, such as generators, airplane propellers, or industrial equipment.

Gas turbines are widely used in various applications, including power plants, aviation (airplane engines), marine propulsion, and industrial processes, due to their efficiency, power-to-weight ratio, and versatility. They play a vital role in modern energy production and transportation systems. Let’s read on to know more about the key components of gas turbines as listed by BVPL Turbine Parts, one of the well-known gas turbine component manufacturers in India

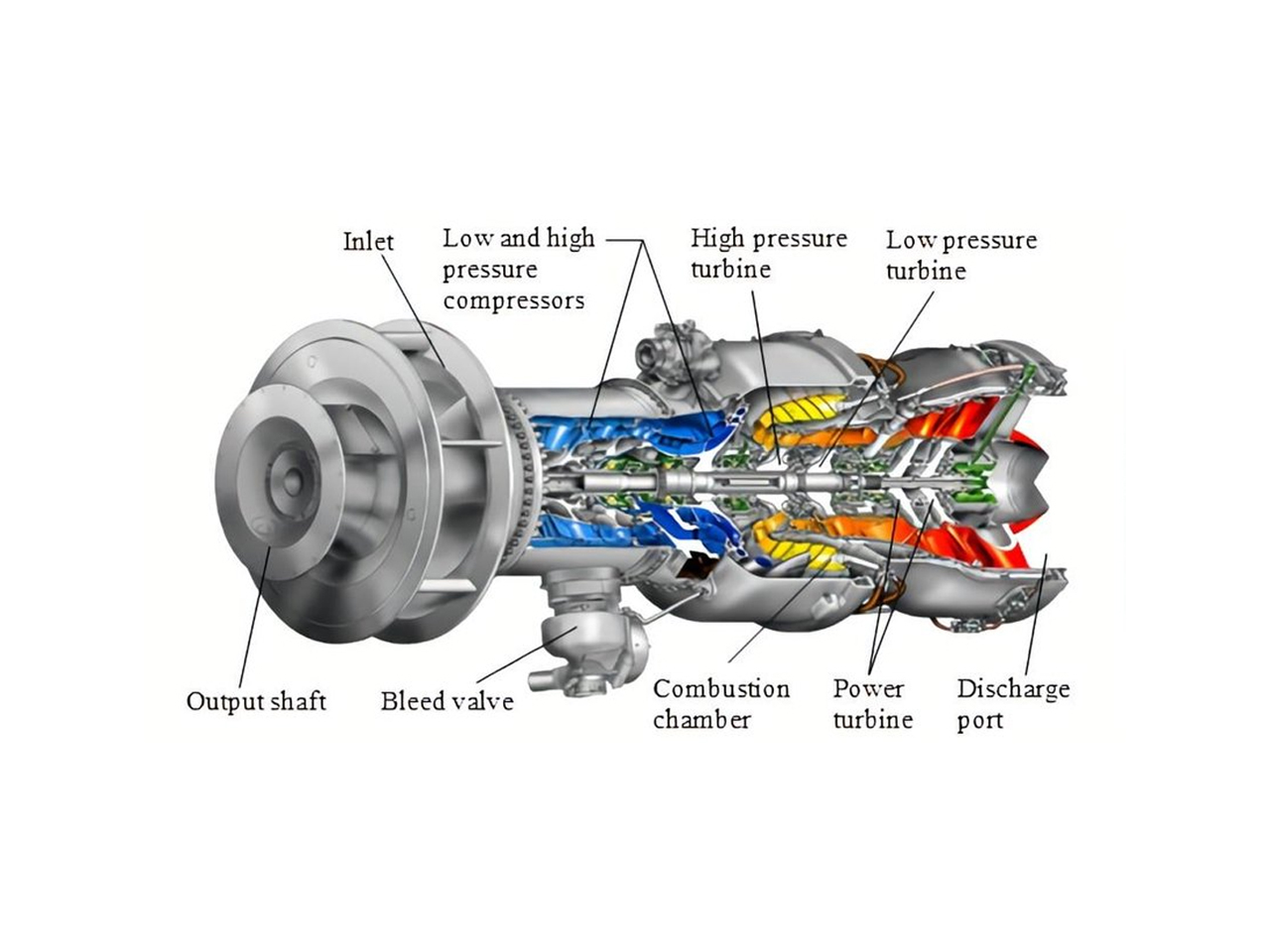

Key Components of Gas Turbine Engines

1. Compressor: Squeezing The Air

The compressor is the first component of the gas turbines, and its primary function is to compress the air that is drawn into the gas turbine. The compressor section typically consists of several rows of rotating blades that increase the pressure and temperature of the air. The compressor is old for compressing incoming air, increasing its pressure and temperature before it enters the combustion chamber. This pressurized air ensures a steady and efficient combustion process, optimizing power output.

2. The Combustion Chamber: Where the Magic Happens

This is where the fuel and air get mixed and ignite to create the high-temperature, high-pressure steam that powers the turbine. The combustion chamber is draw to provide efficient mixing of fuel and air while minimizing emissions.

3. Turbine Blades: Harnessing energy

The turbine blades are critical components that extract energy from the high-temperature, high-pressure gases produced in the combustion chamber. These blades are plan to withstand extreme conditions while converting the gas’s energy into rotational power that drives the turbine. The turbine is the component that converts the energy of the high-temperature and high-pressure gas stream into mechanical energy. The turbine section typically consists of several rows of stationary and rotating blades that extract the energy from the gas stream and transfer it to the shaft.

Also Read: Quality and Expertise: Choosing the Right Gas Turbine Parts Manufacturer

4. Fuel nozzle

Any tube-like part with an aperture through which fluid is introduce and ejected at high pressure is mention to as a gas turbine nozzle. A gas turbine nozzle’s job is to enable fluid movement in parts and procedures that call for high-pressure fluid entrance or exit. Exhaust nozzles are old to discharge exhaust gases, whereas fuel nozzles are nearly new to inject fuel into the combustor. Nozzles are term based on their intended usage. Fuel nozzles are a crucial component of gas turbines because they ensure that air and fuel are well mixed before being catch and burned to produce pressurized gas and heat energy.

5. Exhaust

The main mechanism for expelling waste gasses from the engine core of a gas turbine is the exhaust. By lowering internal fluid pressure and temperature when gasses are deliver from the system, gas turbine engine exhausts are use to regulate the engine’s operation. The exhaust from a gas turbine can also be old to assess the turbine’s efficiency. The exhaust spread is one of the exhaust parameters use in this context.

Gas turbine engines are marvels of engineering, utilizing precise design and intricate components of gas turbines to generate immense power. Understanding the key components of these engines gives us a glimpse into the sophisticated technology that drives modern aviation and energy production. The relentless pursuit of efficiency and innovation continues to propel gas turbine engines into a future of even greater advancements and environmental sustainability.

BVPL Turbine Parts is a gas turbine part manufacturer in India. Being the best gas turbine component manufacturers, all our customers from the start of our foray into the aerospace, gas turbine and steam turbine industries continue to work with us to this day, bearing testimony to our delightful customer service If you are in search of a Gas Turbine Parts Manufacturer In India, visit our website – BVPL Turbine Parts.