Steam turbines have long been at the forefront of power generation. In fact their efficiency and performance are critical for various industries. In India, a country with a burgeoning energy demand, the need for effective and efficient steam turbine components is more significant than ever. Additionally, balancing power output and energy efficiency is paramount to meet the increasing power needs while minimizing environmental impact. So, let’s delve into the world of steam turbine components manufacturers in India and how they are striving to achieve this delicate balance.

The Power Of Steam Turbines

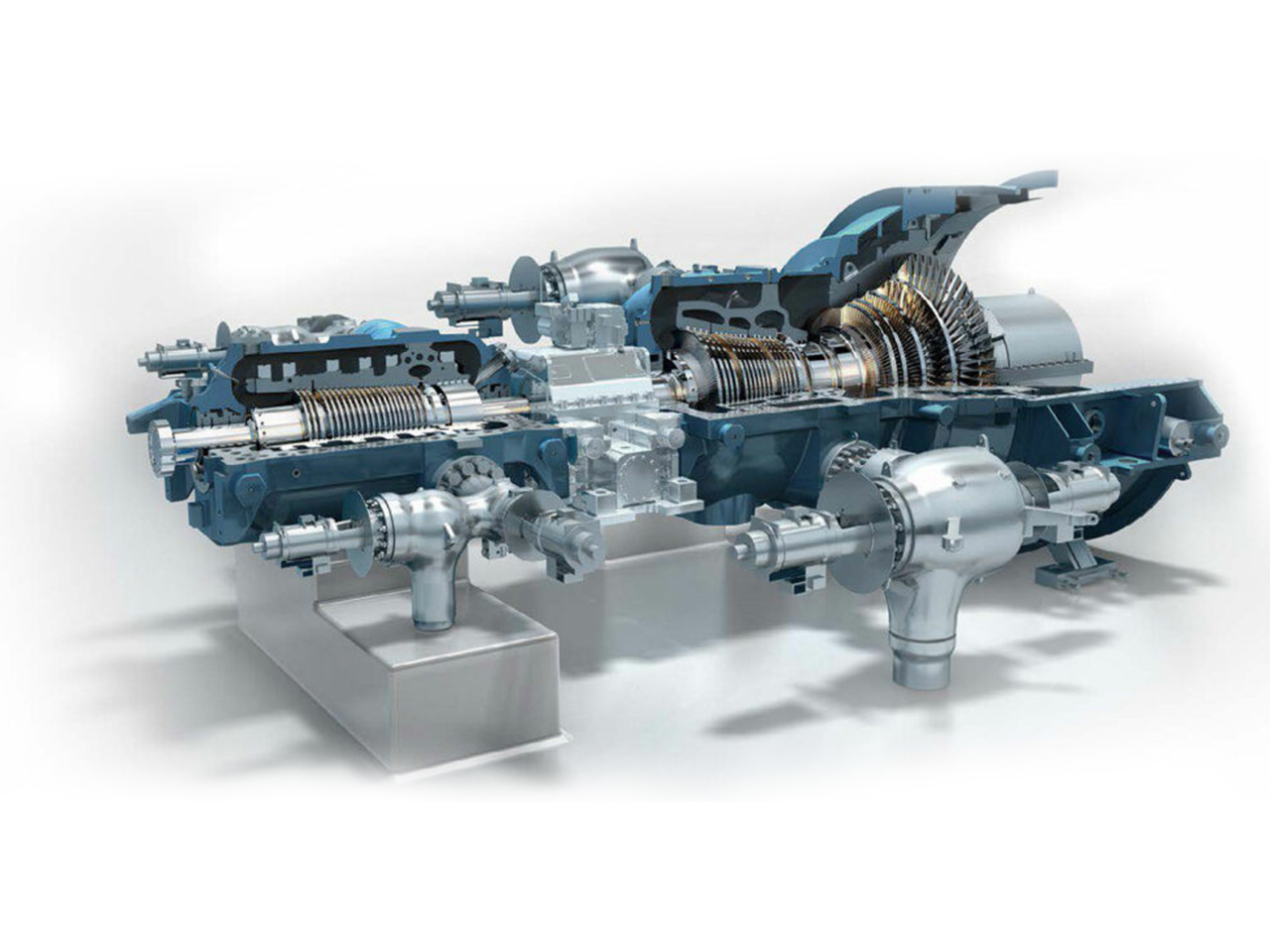

Steam turbines are workhorses in the energy sector, converting thermal energy from steam into mechanical work. This mechanical work is subsequently transformed into electrical power through generators.

Key Components of a Steam Turbine

So, to understand the importance of balancing power and efficiency, it’s essential to recognize the crucial components of a steam turbine:

1. Steam Nozzles and Blades

Steam is directed onto the turbine blades through nozzles. The design and material of these components are critical for optimizing the steam flow and then maximizing the conversion of thermal energy into mechanical power.

2. Rotors and Casings

The rotor is the central rotating part of the turbine. The casing surrounds the rotor and directs the steam flow. Moreover, the design and manufacturing precision of rotors and casings directly impact the overall efficiency and power output of the steam turbine.

3. Bearings and Seals

Proper functioning and efficiency depend on the quality of bearings that support the rotor and seals that prevent steam leaks. Subsequently, these components reduce friction, ensuring smooth and efficient turbine operation.

4. Governor and Control Systems

These systems regulate the speed and power output of the turbine, maintaining stability and optimizing performance according to the energy demand.

Striking the Balance: Power vs. Efficiency

Steam turbine component manufacturers in India and worldwide are finding a challenge to the balance between maximizing power output and maintaining high efficiency. Therefore, power output is essential to meet the energy needs of a growing population and industrial sector. Nonetheless, efficiency is equally critical when it comes to reducing fuel consumption, operational costs, and environmental impact.

Read more at: Steam Turbine and Gas Turbine Components

How BVPL Turbine Parts Is Addressing The Challenge

BVPL Turbine Parts, steam turbine components manufacturers in India, continuously innovating and investing in research and development to improve steam turbine component designs and materials. In other words, we focus on:

1. Material Innovations

Utilizing advanced materials with enhanced durability and thermal properties allows for higher steam temperatures and pressures, resulting in improved efficiency.

2. Optimized Designs

Engineers employ advanced computational tools and simulations to refine the designs of steam nozzles, blades, rotors, and other components, ensuring optimal performance and power generation.

3. Precision Manufacturing

By implementing state-of-the-art manufacturing techniques and quality control processes it ensures that each component meets the required standards, thereby contributing to both power and efficiency.

4. The Way Forward

So, in India’s journey towards sustainable energy production, the role of steam turbines cannot be overstated. Striking the delicate balance between power output and efficiency is therefore equally important.

The evolving landscape of steam turbine and gas turbine components manufacturing in India reflects a commitment to achieving the delicate equilibrium between power and efficiency. With advancements in materials, designs, and manufacturing processes, BVPL Turbine Parts is poised to drive toward a more energy-efficient and sustainable future.