A good-quality engine is a critical component of any machine. Additionally, it is the backbone of every machine to boost its performance. Moreover, along with the engine’s functionality, it is essential to focus on other engine mechanical parts and components for the holistic functioning of the entire machine.

Moreover, learning about machine elements is one of the most critical steps in creating efficient machines that solve the root cause of process problems and allow effortless work. In this blog, we shall unlock the performance of engine mechanical parts, which are a must for many machinery industries. Also, let us give you a sneak peek into their role. But before that, let us know more about engine mechanical parts.

What are engine mechanical parts?

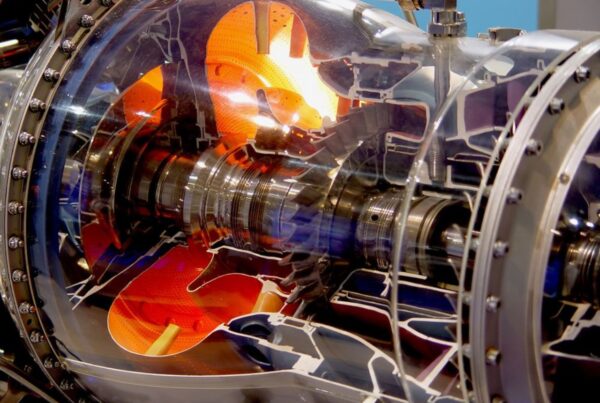

Engine mechanical parts convert thermal energy into mechanical energy. These are critical mechanical components used to drive vehicles and mechanical equipment, improving functionality and performance.

Mechanical engineering parts are used in many industries, including power generation, aviation, automobile, marine, and other industrial applications. Engine mechanicals come in different sizes and types for multiple fields. They are also one of the core technologies of the mechanical industry.

Role of Engine Mechanical Parts

The role of mechanical parts includes the following-

- Holistic functioning

A machine element is considered a vital part of an assembly in mechanical engineering. Also, they are focused mechanical components that perform a single function and cannot be replaced by any other. They work holistically and harmoniously to function and boost performance. In such cases, paying close attention to every machine component is essential.

- Types of Mechanical Engineering Parts

The functionality and role of mechanical engineering parts may differ depending on the types of machine components, which includes –

- General purpose machine elements focused on holistic general purposes with definite shapes and sizes as per standards.

- Customize mechanical components for the machinery industry based on specifications and requirements with special-purpose machine elements.

- Elementary machine parts, such as bolts and nuts, are particular connector components that help connect one component to another for machinery operations.

The technical designs and production of mechanical components require careful attention to many elements to boost machining capabilities. Ensure proper assembly activities to correctly orient, position, and align components for complete functioning.

- High Performance in case of critical applications

Apart from investing in high-quality precision engine mechanical parts, it is important to focus on performance capacity to boost the superior quality of functioning in various industries for better results. Following regular services with professional providers can initiate high machine performance and maintain optimum functioning. Every component of engine mechanical parts has to perform uniformly to boost better performance.

Conclusion

Quality control checks for assembled components deliver high mechanical strength. This allows the engineering mechanical parts to withstand the stresses and strains during operations, thereby ensuring good performance and boosting the overall product life cycle.

BVPL Turbine Parts is a certified engineering parts supplier in Bangalore. They specialize in manufacturing engine and structural parts for aircraft, industrial gas turbines, and steam turbines. Well, that’s not all! BVPL also provides high-quality solutions with the best services for various industries under one roof. It is a one-stop solution for all engine mechanical parts and services at its best under the guidance and expertise of professional engineers.