In a world where precision is paramount, there exists a realm where every fraction of a millimeter counts, and accuracy is not just a requirement but an absolute necessity. Welcome to the fascinating world of the high-precision industry, where engineering meets perfection with intricate designs and meticulous craftsmanship. Let’s unravel the secrets of an industry that thrives on precision – an industry that shapes the very backbone of modern innovation.

Exploring The High Precision Industry

1. The Essence of High Precision

At the core of the high precision industry lies an unwavering commitment to accuracy. Whether it’s manufacturing high precision components for aerospace, medical devices, or cutting-edge electronics, precision is the bedrock upon which this industry stands. The tiniest imperfection can have far-reaching consequences, making every step of the process a meticulous pursuit of perfection.

2. Applications Across Industries

The high precision industry is not confined to a single sector; its influence permeates various domains. From the aerospace sector, where high precision components ensure the safety of air travel, to healthcare, where high precision is essential for medical instruments and devices, this manufacturing plays a pivotal role in advancing technology and improving our lives.

3. Intricate Engineering

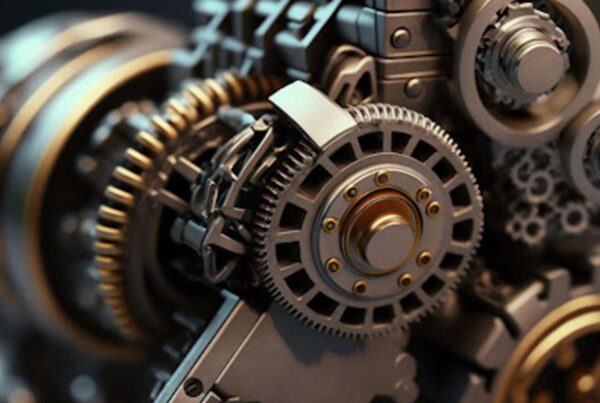

Delving into the heart of high precision manufacturing, we uncover the complex engineering that goes into creating components with unparalleled accuracy. Cutting-edge technologies such as Computer Numerical Control (CNC) machining, 3D printing, and advanced metrology tools are harnessed to achieve levels of precision that were once deemed impossible.

4. Materials Matter

The high precision industry is a masterclass in material science. Engineers meticulously select and test materials to ensure not only precision but also durability and reliability.

5. Innovation and Advancements

In a world that is constantly evolving, the high precision industry is no stranger to innovation. The pursuit of perfection drives continuous research and development, leading to breakthroughs in manufacturing processes, materials, and design. Stay tuned as we uncover the latest advancements that are pushing the boundaries of what’s possible.

6. Human Touch in Automation

While automation plays a significant role in achieving precision, the human touch remains indispensable. Skilled technicians and engineers bring artistry to the science of precision components manufacturing. Balancing the latest technologies with the expertise of seasoned professionals is a delicate dance that ensures each component meets the highest standards. Precision Components manufacturers such as BVPL Turbine Parts also use the latest technology with human touch to minimize chances of error.

7. Quality Assurance

In an industry where precision is non-negotiable, quality assurance takes center stage. Rigorous testing, inspection, and adherence to international standards are the pillars that uphold the reputation of high precision component manufacturers. Discover the stringent measures in place to guarantee that every product leaving the production line is engineered to perfection.

As we draw the curtain on this exploration of the high precision industry, we leave behind a trail of awe and appreciation for the meticulous craftsmanship that shapes our modern world. From aerospace to healthcare, and every sector in between, the high precision industry is the unsung hero, ensuring that the devices we rely on and the innovations we marvel at are, indeed, engineered to perfection. Step into this world of precision, and you’ll never look at the intricacies of technology the same way again.